Scientific expertise and advancement are at the root of USP’s work to develop quality standards and are the foundation of all our related activities and programs that help ensure the quality and safety of medicines, dietary supplements and foods around the world. Through the development of reference standards for specific ingredients, impurities and finished products, as well as our written standards for processes such as tests, procedures, and packaging and distribution, we set the standard for the science of quality.

CD34+ standard helps with lifesaving transplants

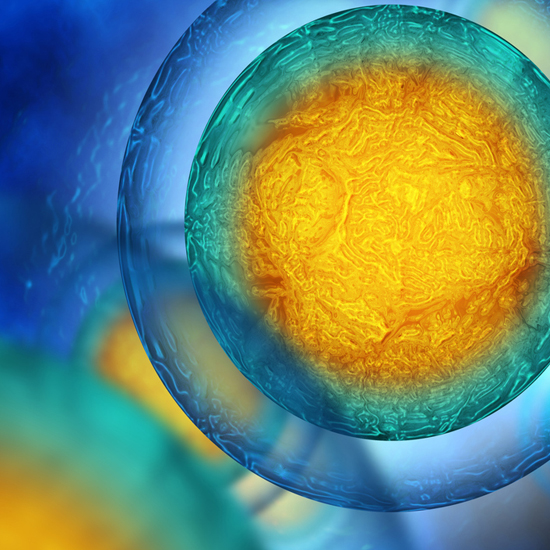

“When patients with leukemia or other conditions need a bone marrow transplant, treatment success depends on choosing a viable transplant sample with the right amount of blood stem cells to rebuild the patient’s immune system. Because there are very few stem cells in bone marrow, getting an accurate count can be a challenge.

This year, we made refinements to a standard we had introduced in 2017 so that the testing procedure could be even more useful and impactful. This test relies on the measurement of a marker called CD34+, which is present on the surface of the stem cells. In addition to stem cell transplants, the test is used by researchers to measure stem cells in clinical samples as they work to develop new lifesaving treatments. This standard helps patients get the most promising transplant of blood-derived stem cells – the very thing which could save their lives.”

Vice President, Science, Global Biologics

Protecting the quality of inactive ingredients

“Most people don’t think much about excipients, which are considered the “inactive” ingredients in medicine. But these are actually critically important to how well a drug works in the body, helping the pill hold together or allowing the medicine to be absorbed properly in the body. And poor-quality excipients can be a big risk to patients.

We recently published draft standards seeking comments from international stakeholders revising the standards for three types of saccharin. Today, saccharin is used to help make medicines – which would otherwise taste pretty bad – palatable for patients. It is also used as an excipient for medications delivered intravenously or by aerosol, which means it’s critical to control impurities. This work is important because saccharin can contain harmful impurities that can develop during some manufacturing processes.”

Senior Director, Excipients